We wanted to show that the technology behind the QEG is a very real, very practical mechanism. The only reason why it is not well known is because it has been suppressed and underutilized. However, with changing times and the increasing need for alternative forms of energy, the QEG technology is already being employed in major motor manufacturing companies and is still slated to dominate the renewable energy industry in the future despite newer technologies that are coming out. This is because of its simple construction and low manufacturing costs.

The following is the first full chapter of our QEG eBook published here in its entirety written by Dijon Rios (AKA Tivon Rivers). We wanted to publish this freely to provide a reference source to help bridge the gap in the further development and distribution of this alternative form of energy creation.

THE LEGACY

A brief history of the reluctance generator

By Dijon Rios, Space Visuals Seaside Engineer

The generator build in this course is of the ‘reluctance’ type, and

can also be defined as a variant of the following: variable induction

generator and flux alternator. To better understand why this class of

generator is slated to still dominate the clean tech sector (in spite of

new technologies), we must first recap the development of this

technology.A brief history of the reluctance generator

By Dijon Rios, Space Visuals Seaside Engineer

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Electric motors produce either linear or rotary force (torque), and are found in the following applications: industrial fans, pumps, machine tools, household appliances, power tools, and disk

drives. They can be powered by either direct current sources (i.e batteries, motor vehicles or rectifiers), or by alternating current sources (such as from the power grid, inverters or generators). General-purpose motors with highly standardized dimensions and characteristics provide convenient mechanical power for industrial use. The largest of electric motors are used for ship propulsion, pipeline compression and pump applications with ratings approaching 100 megawatts. Electric motors are classified by electric power source type, internal construction,

application, type of motion output, and so on.

Generators are motors operated in reverse, whereby it is an electrical machine that converts mechanical energy into electrical energy. Hence, to understand the origin of the reluctance generator, we must delve into the 125 year history of the reluctance motor and why this technology is anticipated to still dominate the renewable energy market in the 21st century.

In the 1880s, many inventors were trying to develop workable AC motors because of AC’s advantages in long distance high voltage transmission. In 1888, Nikola Tesla presented his paper ‘A New System for Alternating Current Motors and Transformers’ to the American Institute of Electrical Engineers (AIEE) and described three patented two-phase four-stator-pole motor types: one with a four-pole rotor forming a non-self-starting reluctance motor, another with a wound rotor forming a self-starting induction motor, and a third truly synchronous motor with separately excited DC supply to rotor winding.

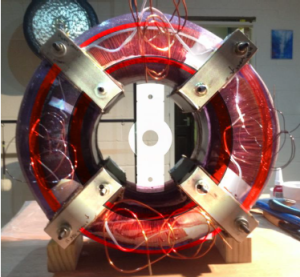

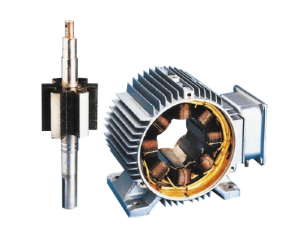

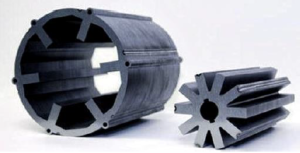

Switched reluctance motors have a rotor that has no magnets or windings. It is a salient piece of iron. The salient stator has a simple construction.

The design for the reluctance motor was first cited in patent 381,968 May 1, 1888 by the inventor Nikola Tesla. He conceived of an embodiment of a variable inductance motor with no magnets, and where the iron rotor contained no windings. The modern day Switched Reluctance Motor (SRM) remains true to Tesla’s patent, as it contains no brushes or permanent magnets, and the rotor has no electric currents. Instead, torque comes from a slight misalignment of poles on the rotor with poles on the stator. The rotor aligns itself with the magnetic field of the stator,

while the stator field stator windings are sequentially energized to rotate the stator field. The magnetic flux created by the field windings follows the path of least magnetic reluctance, meaning, the flux will flow through poles of the rotor that are closest to the energized poles of the stator, thereby magnetizing those poles of the rotor and creating torque. As the rotor turns, different windings will be energized, keeping the rotor turning.

Clean technology is a contemporary issue, and the international community has accepted the environmental dangers of false economies and the toxification of the environment. Renewable energy is one of the hot topics when it comes to a viable solution, and both wind and solar generation are but a few of the renewable energy power sources that help.

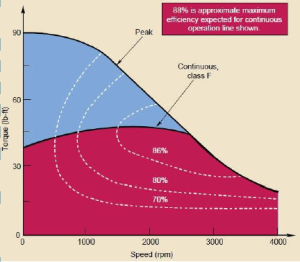

In recent decades, reluctance machines have become an important alternative in various applications in both the industrial and domestic markets. They have good mechanical reliability, high torque-volume ratio, high efficiency, plus low cost. Although the technology is less evangelized as a generator, there are a few studies of its application in the aeronautical industry and in wind based energy applications.

Although the synchronous and induction machines dominate the market of wind energy applications, the reluctance machines are the subject of current investigation and are a valid alternative for this field. Compared with the classical solutions of machines integrated in wind applications, its simplified construction associated with the in existence of permanent magnets or conductors in the rotor results in lower manufacturing costs; in addition both the machine and the power converter are robust. The low inertia of the rotor also allows the machine to respond to rapid variations in the load.

Associated with these characteristics, reluctance machines may now employ electronic control systems that enable rapid changes in machine function such that its performance is optimized (making them Switched Reluctance Machines or ‘SRM’). The structure of reluctance technology is not as stiff as their synchronous counterparts, and due to its flexible control system; is capable of absorbing transient conditions, thus supplying more resilience to the mechanical system.

The machine has an inherent fault tolerance, especially when under an open-coil fault (in the windings) and in the power converter (external faults). Under normal operation, each phase of Switched Reluctance Generator (SRG) is electrically and magnetically independent from others.

Reluctance technology is generally felt to be louder than conventional machines, but this can be remediated with adequate mechanical design, which can do a lot to improve these figures. In addition, all reluctance generators have the following advantages:

-simple construction, low manufacturing cost, low inertia,

-fault tolerance and the ability to operate in a high temperature environment

-present R&D for drives in power source applications that include hybrid electric vehicles, aerospace power systems and wind engines.

The aerospace and automotive applications are characterized by high-speed operation. Constant mechanical power is provided over a wide speed range, while the wind energy applications are characterized by low-speed and high-torque operation.

If 80% efficiency isn’t enough, know that companies are embracing this technology to position themselves in the renewables sector. For example HEVT has developed their switched reluctance motor technologies and are poised to empower the next generation of electric motors, making performance leaps with unmatched reliability and reduced cost volatility due to the use of zero rare earth minerals. They emphasize environmental benefits of having technologies that do not require the use of neodymium magnets in their statement:

“To date, most motors are manufactured in China because rare earth mining and refining capacity is concentrated in China. Mining and refining rare earth metals is a process that causes air, land and water pollution because these metals are typically located in bands of ore that include radioactive thorium. Not only do our technologies enable electric motors free of rare earth metals – thereby reducing environmental and public health impact – but the manufacturing process is disruptively elegant – we can scale production of our motors quickly and globally, creating local jobs in the process. Finally, our motors are highly reliable and efficient, high-performing and less costly: we reduce the initial and lifetime cost of ownership – a critical building block to enabling adoption of renewable energy, energy efficiency and sustainable transportation technologies in the U.S. and throughout the world.” – HEVT

You’ll learn how to build your own efficient reluctance generator.

Finally, by building the generator in this ebook you will be well positioned to participate in ongoing experiments in power regeneration research being undertaken worldwide. You will invariably test many configurations to get a better understanding of the methods other developers are using to recycle excess energy from the environment. There are generator builds that focus solely on the radiant techniques employed in countless Tesla patents, while others are using stored inertia in flywheels, gearing, and pendulums as an intermediary between the motor and generator as a means of an self-contained energy regeneration system (i.e. patents US 20080143302 A1 and ES2119690).